Product

Configuration

Configure Products in Real-Time on the Order Desk or Online

What is Product Configuration?

Product Configuration in ERP123 utilizes an integrated software tool known as a Product Configurator to guide the end user through a series of questions that the user must answer. These answers tell ERP123 how to construct the product structure based on the product options chosen

It's the fastest way to create orders

Product Configurators are typically used on an order desk or a website where there are a finite number of available product options. You can create product configurations ranging from very simple to complex and parametric. Data generated in Product configuration is used to:

Dynamically create the work order

Calculate the list price for the product

Create a “smart part number” for the options chosen

Want to Learn More About Product Configuration?

ERP123 delivers the functionality You Need

Configurations

Build simple or multi-level production configurations from core product data

Product Data Management (PDM)

Simple creation and updating

Parametric answers

Base model with add or remove options

Configurable pricing

Sales / Quoting

Combine standard, estimated and configurable items on a single quote

Mobile CRM and Contact Management

CAD Interfaces

Order and Quote History

Easy conversion of quotes to orders

Planning

Product work orders are created by the configurator and used in planning

Long Lead-Time Materials

Delivery Management

Shortage Management

Facility Loading

Manpower Planning

Supply Chain

Combine standard, estimated and configurable items on a single quote

MRP

Subcontracting

Purchasing & Approvals

Lot & Serial Traceability

Allocation Management

Shipping & Receiving

Vendor Returns

Manufacturing

Combine standard, estimated and configurable items on a single quote

Manufacturing Execution (MES)

Electronic Documentation

Label Printing

Detailed Scheduling

Warehouse Management

Shop Floor Time Management

Quality Management

Finance

Multi-facility, multi-currency user-configurable General Ledger, Accounts Receivable, and Accounts Payable

Multiple periods

Item Based Costing

Milestone Payment Schedules

Commission

Work-in-Process Management

Deferred Revenue

Revenue Recognition

Metrics & Reporting

Combine standard, estimated and configurable items on a single quote

Project-based P & L

Labour Efficiency

Price Variance

Detailed Product Costing

On-time Delivery to Target

Vendor Delivery Performance

Industries That Use Product Configuration

Lighting

Paint Colors

Fabrics

Chairs

Audio & Electronics

Musical Instruments

Promotional Products

Computers

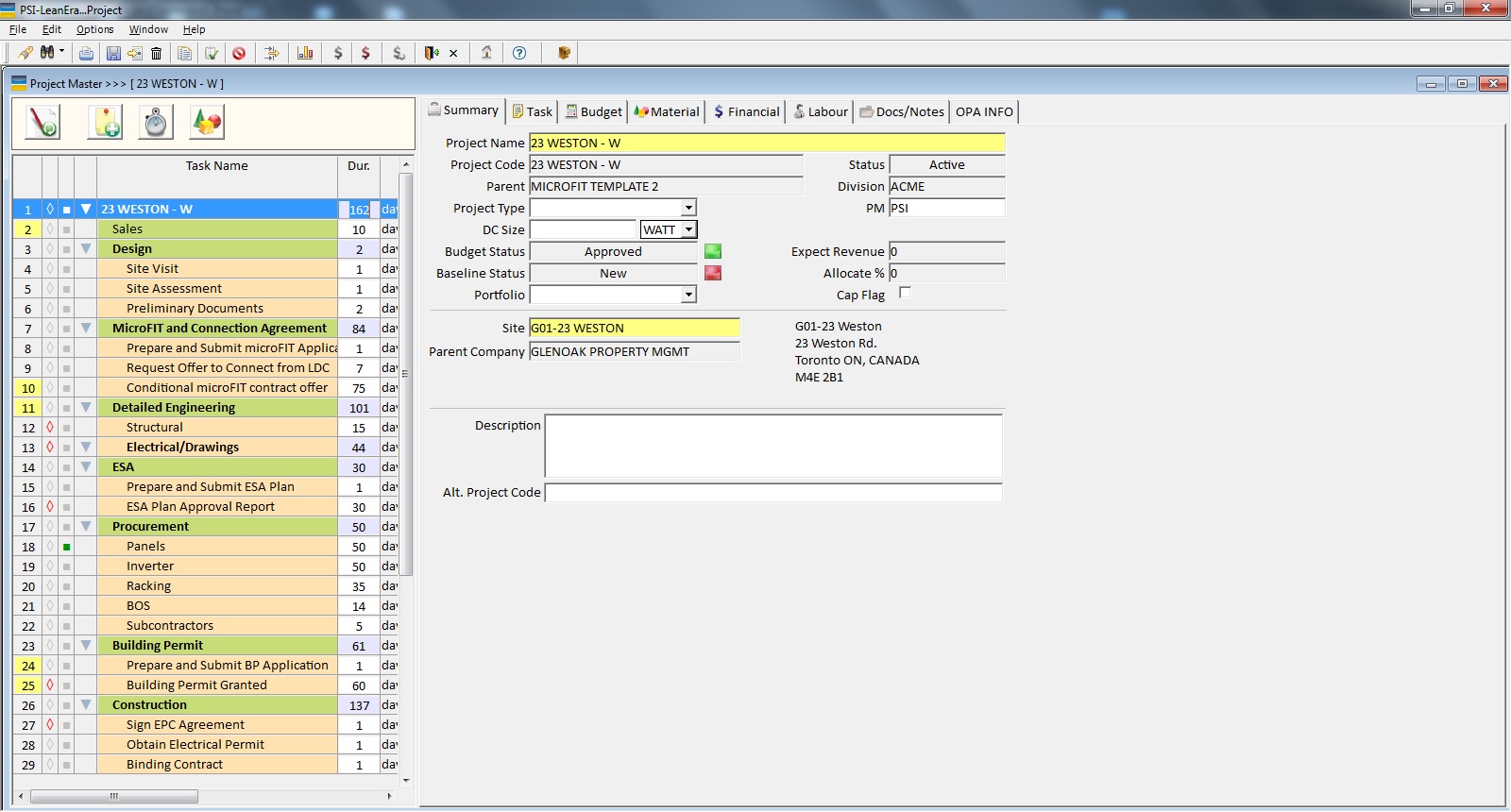

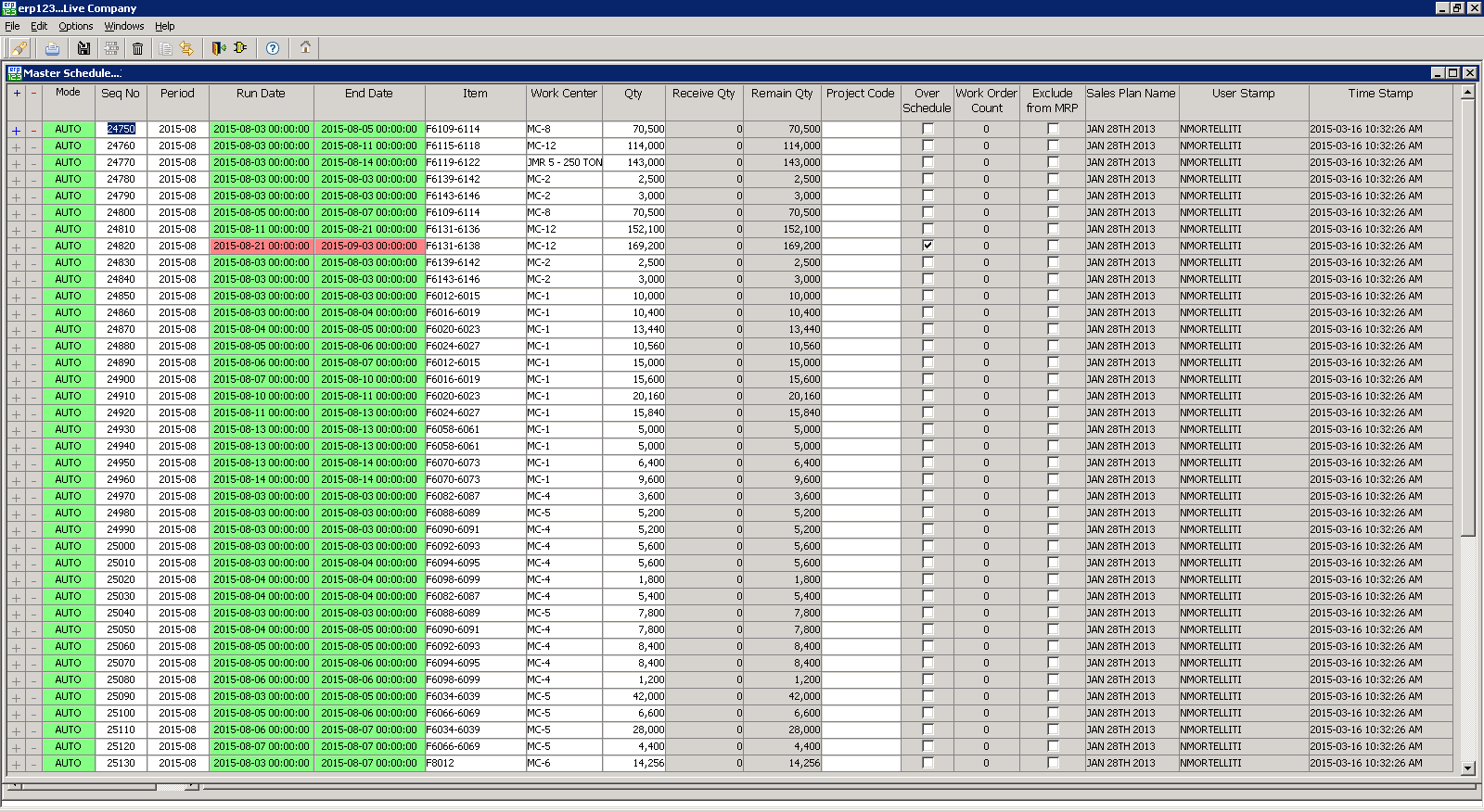

Screen Shots

A few selected screen shots from the ERP123 Project-Based Manufacturing vertical solution